Difference between revisions of "3d printer"

(Added a bit on safety re: fire hazard.) |

|||

| (4 intermediate revisions by 3 users not shown) | |||

| Line 8: | Line 8: | ||

|serial = n/a | |serial = n/a | ||

|arrived = April 2013 | |arrived = April 2013 | ||

| − | |doesitwork = | + | |doesitwork = WORKING |

|contact = Ben Bergman/Stefan Asmundsson/Andrew Orr | |contact = Ben Bergman/Stefan Asmundsson/Andrew Orr | ||

|where = n/a | |where = n/a | ||

|value = $1700 | |value = $1700 | ||

| − | |itemphoto=[[File: | + | |itemphoto=[[File:3dprinter_1.jpg]] |

}} | }} | ||

| Line 36: | Line 36: | ||

There is a dedicated 3D printer workstation right next to the printer. This is running Ubuntu 12.04 and has FreeCAD, Slic3r, and Printrun (Pronterface, Pronsole, etc.) set up and ready to go. All the parts (monitor, tower, mouse, keyboard) are labelled and should stay with the workstation at all times. | There is a dedicated 3D printer workstation right next to the printer. This is running Ubuntu 12.04 and has FreeCAD, Slic3r, and Printrun (Pronterface, Pronsole, etc.) set up and ready to go. All the parts (monitor, tower, mouse, keyboard) are labelled and should stay with the workstation at all times. | ||

| − | ==How to print (Work In Progress)== | + | ==How to print ('''Work In Progress''')== |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | Due to recent adjustments and firmware updates, the instructions on how to use the printer are currently being reworked. Don't even think about going to a previous version of this wiki page to find them. | ||

===Choosing the right temperature=== | ===Choosing the right temperature=== | ||

| Line 109: | Line 78: | ||

** 220c seems to work good | ** 220c seems to work good | ||

* Bed needs to be leveled *again* | * Bed needs to be leveled *again* | ||

| + | Links: | ||

| + | |||

| + | http://reprap.org/wiki/Calibration | ||

| + | |||

| + | http://reprap.org/wiki/Print_Troubleshooting_Pictorial_Guide | ||

| + | |||

| + | https://www.simplify3d.com/support/print-quality-troubleshooting/ | ||

==Things we need to print== | ==Things we need to print== | ||

Latest revision as of 05:53, 1 November 2015

|

Contents

General

- Owner/Loaner: SkullSpace

- Serial Number: n/a

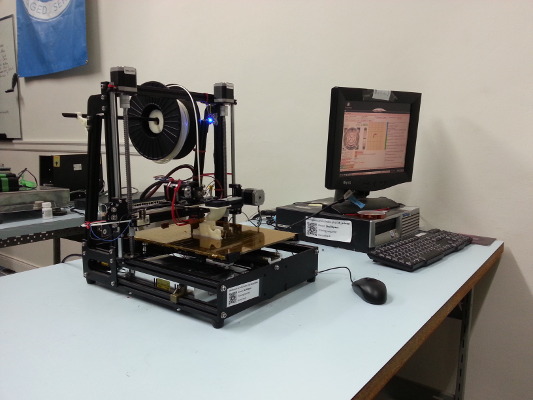

- Make/Model: MendelMax 2.0 Beta

- Arrival Date: April 2013

- Usability: WORKING

- Contact: Ben Bergman/Stefan Asmundsson/Andrew Orr

- Where: n/a

- Training Needed: YES

- Hackable: NO

- Estimated Value: $1700

Label

MendelMax 2.0 Specs

http://www.makerstoolworks.com/support-and-docs/

- Print Area Dimensions: 245 mm x 315 mm x 225 mm

- Print Area: 17,364.8 cm3

- Printer Dimensions: 450 mm x 340 mm x 460 mm

- Usable Maximum Print Speed: 250mm/sec or more depending on the part, print material, and extruder

- Usable Maximum Movement Speed: 500+ mm/sec

- Layer Height: .1-.4mm, user selectable. Lower layer heights are also possible.

- X & Y Axis Resolution: .0125mm

- Frame: All aluminum

- Movement: linear rail (X and Y axis), precision shafting and bushing (Z axis)

- Heated Bed: 24V 200W Heated Bed included

- Power Requirements: 110-220 VAC

- Hotend: J-Head Mk V-BV 0.4 mm / 3.0 mm

Dedicated Printer Workstation

There is a dedicated 3D printer workstation right next to the printer. This is running Ubuntu 12.04 and has FreeCAD, Slic3r, and Printrun (Pronterface, Pronsole, etc.) set up and ready to go. All the parts (monitor, tower, mouse, keyboard) are labelled and should stay with the workstation at all times.

How to print (Work In Progress)

Due to recent adjustments and firmware updates, the instructions on how to use the printer are currently being reworked. Don't even think about going to a previous version of this wiki page to find them.

Choosing the right temperature

For ABS, 210c was working good for us. What you should do it heat the hotend up to 230 or so and try extruding 10mm and watch it carefully. If it smokes, bring the temp down to 220 and try again, you want it just under where it smokes.

ABS on bare glass

OhmEye says he prints ABS on bare glass:

(13:59) ( OhmEye) xorrbit: I use 135-140C for the glass temp and first layer speed of 30mm/s with ultimachine ABS and can print most things with only minor lifting issues if I don't have any breeze in the room.

Todo

- Tuning (see below)

- Make sure there are no "spare parts" sitting around that are actually needed and were missed

- Flash Arduino Mega 2560 *bootloader* using ISP so we can update firmware from linux

- Install heatsinks on pololus (Andrew has ordered these)

- Install/mount fans on heatsinks on pololus (Andrew has ordered these)

- Install end stops and configure homing

- We should do homing like below if we can, a cursory look at the firmware config file suggest that we can

- Verify/configure software end stops and axis dimensions in firmware config file

- Install power switch

- Cover up 120v exposures

- Cover for power supply terminals

- Grounded box for ac plug

- Replace the rest of the temp plastic clips with zip ties

- Print/acquire cable chain for carriage wiring and X motor wiring

- Set up dedicated computer with pronterface, slic3r, and freecad

- Nice big "don't touch you will get burned" / etc sign should be printed and displayed

- UPS of some kind for long print jobs

- Webcam for monitoring print status

Tuning

- Extruder hotend and bed thermistors were both verified to be working properly

- Z axis was raised to prevent grinding and leveled

- Extruder

- Discovered high print speed causes abs to accumulate in the gear threads which causes slippage

- 300 mm/min is way too fast

- folks on irc say keep it at 80 mm/min for calibration

- 220c seems to work good

- Bed needs to be leveled *again*

Links:

http://reprap.org/wiki/Calibration

http://reprap.org/wiki/Print_Troubleshooting_Pictorial_Guide

https://www.simplify3d.com/support/print-quality-troubleshooting/

Things we need to print

Stef printed the x end stop, y end stop, z end stop, and fan mounts!

STL Archives:

https://www.dropbox.com/sh/3uyotd400xp2ef5/AvakF1Vw25/STLs

http://ohmeye.com/download/mendelmax/

- Fan duct

- cable chains

- As per https://dl.dropboxusercontent.com/u/95642557/XCableChain1.jpg and https://dl.dropboxusercontent.com/u/95642557/XCableChain2.jpg

- http://www.thingiverse.com/thing:40124

- ScottGreen on #makerstoolworks has some cable chain end STLS he should be posting soon

Flashing new firmware

http://www.makerstoolworks.com/support-and-docs/download-center/

Currently we have the MendelMax 2.0 no end stop firmware running on it, modified to use a baud rate of 230400. It uses an Arduino clone called the Taurino that is similar to a Arduino Mega 2560.

The flashing procedure is to load up the Arduino software and configure it as for an Arduino Mega 2560, compile and flash. It did not work on linux but worked worked fine on Windows with the Taurino drivers installed.

Okay so apparently the default taurino *bootloader* does not work with mac/linux so we need to flash the normal Arduino Mega 2560 bootloader onto it. This has to be done using an ISP programmer or another arduino actiing as ISP. After this is done we should be able to flash new firmware via mac/linux.

Post-flash verification steps

After flashing a new firmware a few things should be sanity checked:

NOTE: NEVER unplug a motor while the MendelMax is powered (even via usb!), these motors idle charged and unplugging them while powered will blow a pololu motor driver (and this costs $15 per driver!)

- extruder are not running reversed

- x, y, z motors are not running reversed

Software

Slicing

slic3r is a popular slicer and OhmEye has a MM2 tuned config here we can start from:

http://ohmeye.com/download/mendelmax/ohmeye_slic3r_mm2_example.ini

( OhmEye) that config file I linked is set for a .35mm nozzle with .25mm layers using sane settings.

( OhmEye) I make heavy use of slic3r's presets to manage a lot of configs. One thing I seem to do differently from most people is that I avoid as much printer or filament specific settings in my config as I can, so no heater control or filament adjustments.

( OhmEye) I adjust temps and extrusion flow at the printer so I can print the same gcode file without reslicing with any filament

( OhmEye) when I change filament, I just adjust the temp and flow settings and am good to go

Printer control

Control it with Pronterface using a baud rate of 230400.

The stock MendelMax firmware has the extruder running backwards so the plug shoud be flipped (ie blue wire away from the power connector).

We are working on setting up a dedicated computer for slicing stls and running prints.

Modelling

FreeCAD is the recommended modeling tool, but anything that can produce STLs should work:

Build Issues

A list of issue we had when building and how we fixed it, suitable as feedback to the beta program:

- Plate had wrong side counter-sinks

- MakersToolWorks guy said to use low profile screws, so we picked some up from home depot and it works great

- One of the tighter tolerance car bushings had the alignment notch in the wrong spot

- We snipped off the alignment notch as we determined it was not required

- Missing allen key for securing belt pulleys to X and Y motor shafts.

- Andrew had one he used to secure belt pulleys to the motor shafts (1.25mm).

- Guide rail for y-axis not countersunk.

- Working with minimal clearance between rail mounting screws and bed leveling screw. Be careful when adjusting level on the single arm of the bed mounting plate.

- Working with minimal clearance between rail mounting screws and bed leveling screw. Be careful when adjusting level on the single arm of the bed mounting plate.